We follow a boutique approach, developing specific recipes for any specific customer issue.

POLYOLEFIN CATALYSTS

We all know the problems associated to Plastics materials, especially when it comes to single-use and/or unproper or wild disposal. Yet Polymers -the correct word for plastics- have provided an unvaluable contribution to our societies. Mentioning but a few examples, polymers have enabled the development of safe and durable piping networks for water supply across the globe, car weight has been dramatically reduced, resulting in lowering gas emissions, food safety has been improved, resulting in less health concerns and less wasted food.

Whilst it is everyone’s responsibility to ensure that Polymers are properly used and properly disposed of, at CHEMIUM we believe we can do more by developing catalysts that will bring more efficiency to the polymers manufacturing process, and therefore reduce their environmental footprint.

Further, catalysts also allow to tailor the polymer properties, hence improving their efficiency in use. As an example, the wall thickness of pressure pipes used for water and gas networks has been reduced by around 50% over the years, thanks to a combination of process and catalyst improvements in the polymer manufacturing.

OUR APPROACH

With a track record of nearly 10 years, CHEMIUM is now recognised as a reliable supplier of advanced catalyst solutions for olefins polymerisation, developing tailored catalyst recipes to address specific customer needs.

A s each plant has its specificities, we have a boutique approach, meaning that we will take any customer issue, be it related to process stability or to product performance, as a challenge that deserves the development of a tailored solution. Our specialists perform the development, scale-up and commercialization of specific catalyst recipes from laboratory to industrial scale. Once a new solution is adopted, we pride ourselves in the reliability and consistency of our supply.

Any project starts with a specific customer issue, which can range from manufacturing problems, such as fines formation, low productivity, heat transfer problems,… to product performance, and very often a combination thereof. All these problems bear a Catalyst component in their solution, but not only. We first review thoroughly the issue with the customer experts, so that we understand the plant constrains and limitations.

O

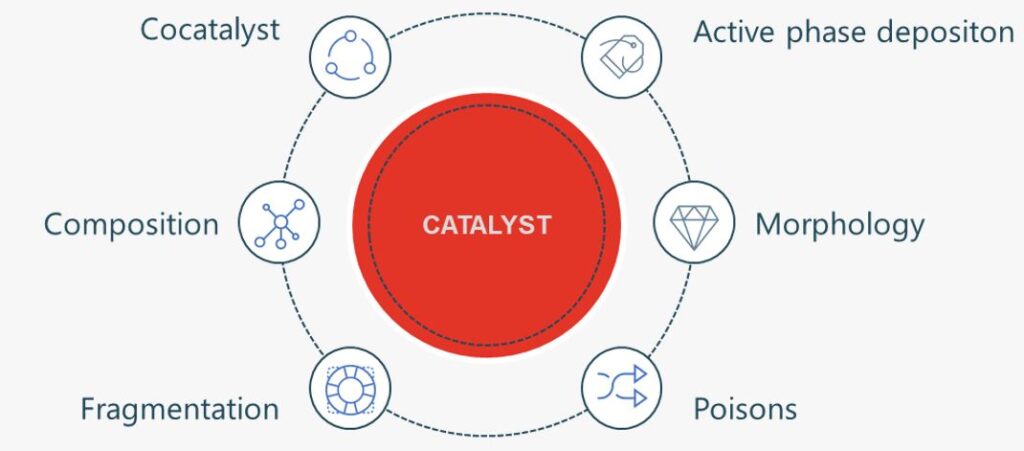

ur approach is about using the Catalyst design/engineering as a toolbox to resolve any of the abovementioned problems. We carefully check which parameters might be responsible for those particular issues and work on those particular parameters or on combination thereof to provide a solution to the customer’s problem.

Our expertise covers all polyolefins catalyst families, from Chromium catalysts (Phillips), Ziegler-Natta Catalysts and Metallocenes and allow us to leverage all the aspects of Catalyst design, from support morphology through deposition techniques to chemical composition and cocatalyst interaction.

OUR CAPABILITIES

R&D center - Louvain-La-Neuve

Our R&D centre is located in Louvain-la-Neuve (Belgium). We dedicate ourselves to the development of catalysts for polyolefins production and resolving Customer problems since 2013.

Our research activities are focused on analysis of catalyst structure-performance

relationship and optimization of catalyst formula as well as technical matters related to the catalyst integration into the industrial process. The R&D facility also provides technical support to the customers.

CHEMIUM's R&D facilities

Key to our catalyst development activity is our capability to anticipate the catalyst response in the industrial process. We dedicate significant efforts in developing and maintaining state-of-the-art facilities that allow us to replicate the industrial polymerisation conditions.

Our Compact Automated System for polymerisation is suitable for running experiments with all classes of catalysts for polyolefins production in slurry and gas phase.