Exploitation to re-consider critical synthesis steps. We provide ready-to-use, fully automated,

efficient and intrinsically safe solutions that can be integrated in any chemical plant.

THE FINE CHEMICAL INDUSTRY

Within the chemical industry, the fine chemical segment is providing the most extended range of synthesis tools to support highly dynamic end markets such as: pharmaceutical, agrochemical or electronic industries.

Since decades, the main success of the fine chemical segment has been its ability to provide its business partners flexible assets to run multistep synthesis. As the main focus was flexibility, multipurpose units became the standard operation model, based on batch chemistry.

Active ingredients becoming more and more complex, especially in the life science industry, a single partner/site is often not able to offer all and every type of chemical transformations needed. It has therefore become quite common to produce new chemical products across several sites and partners, resulting in ever more complex supply-chains, logistics and Quality Control issues.

Beside the multipurpose unit model, several CDMO have developed very specific capabilities to handle dangerous or highly energetic chemistries hence widening the choice of chemical transformations but also increasing the complexity of the global supply chain of active ingredients.

OUR VISION

At CHEMIUM we recognise that the fine chemical players are increasingly focused on integration of ever more complex sets of reactions on the one side, and an ever-stricter quality environment on the other.

CHEMIUM ambition is to support them by offering ready-made solutions for specific chemical reactions which they can easily integrate in their own manufacturing lines, hence eliminating the need for outsourcing or delocalising, reducing supply-chain complexity, lowering transportation volumes and most importantly keeping tighter control on the overall production chain and the product quality.

W e achieve this by challenging the established practices in the light of recent advances in technologies, such as Flow Chemistry or Data-driven optimisation (AI), by leveraging techniques used in other industry segments, but also by proposing innovative value propositions that offer enhanced flexibility to our partners.

MgFlow

An entirely re-designed, continuous process for Grignard reagents production

Discovered by Victor Grignard in 1900, Nobel Price 1912, this family of magnesium-based reagents is largely used in the industry for the key chemical transformation that leads to carbon-carbon bond formation, giving to chemists the ability to build or extend the carbon backbone of chemical entities. This amazing chemistry has proven to be a key element in the production of such useful products as Vitamin A, hypertension treatments or high purity materials for the electronics industry.

However, the preparation of such Grignard reagents in large quantities in batch reactors raises very serious safety concerns. The reaction, which has to be made under inert conditions, is highly exothermic and requires a tricky initiation phase that may turn to be uncontrollable if not handled in the right way, due to energy accumulation.

MgFlow : PROCESS SAFETY BY DESIGN

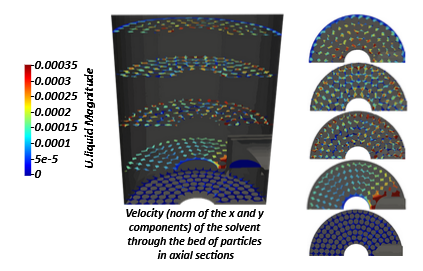

Based on the Flow Chemistry concepts and advanced simulation techniques, CHEMIUM has developed a novel, safe, reliable and highly flexible continuous flow technology, to produce, ready to use, Grignard solutions.

Thanks to a dramatic increase of reaction kinetics, the hold up volume is several orders of magnitude lower than in conventional reactor set-up, hence reducing the energy accumulation potential to non-hazardous levels.

Furthermore, the excellent heat transfer of the system allows for a very tight temperature control, resulting in homogeneous reaction conditions, maximum efficiency and minimized side-reactions.

Our continuous flow technology being the best choice to quickly find optimum safe reaction conditions and to support fast scaleup from liters to multi metric tons capacity, covering all steps of new product development.

CHEMIUM‘s value proposition also includes the ability to produce directly, at customer site, their captive Grignard solutions using our mobile skid equipment, that can be connected to batch or continuous reactions environment.

Quality

Real time quality monitoring with PAT, Consistent quality by design.

Financials

Limited CAPEX, Reduced OPEX, Shorter supply chain (on site skid).

New Development

Shorter development time, Easy screening of solvents, Fast scaleup.

Process Efficiency

Increased flexibility, Waste reduction, Energy efficiency, High level of automation, Plug & Play, Smaller footprint, AI Powered.

Process Safety

Less work-in-process materials, Optimum thermal and mass transfer, Safety by design.

COMMERCIALLY AVAILABLE GRIGNARD SOLUTIONS

CHEMIUM, as a supplier and manufacturer of Grignard Reagents, commercially provides a whole range of Grignard solutions. CHEMIUM’s value proposition also includes the ability to produce custom-made Grignard solutions.